The resulting point clouds, which represented the surface of the superstructure, gingiva, and bone, were matched with the a priori information by means of the GOM Inspect software, according to Habor et al. For both scans, the grid spacing resolution was set to 50 × 50 µm and the depth of scanning was 4.4 mm. During the first scanning, the ultrasound probe was positioned at an angle of 90° to the long-axis of dental implant, whereas in the second scanning the probe position was at an angle of 60° to the dental implant ( Figure 3). In order to optimize our HFUS scans with respect to the specular bone surface by use of a single-element system, each sample was scanned twice.

Galileos viewer download sirona software#

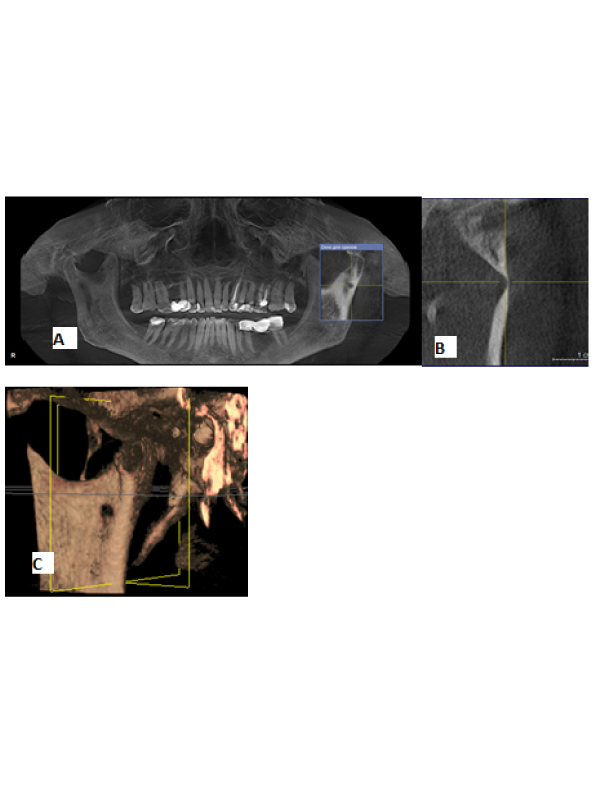

However, those systems are built for standard clinical applications, and hence do neither provide the HFUS range nor the software flexibility required for this application. In this mode ultrasound scans acquired from multiple angles are merged together in order to enhance the homogeneity of the entire scan, especially if specular surfaces, like bone or dental crowns, are involved. Commercial multi-channel ultrasound array systems usually provide a compound scan mode. Thus, the scanning was performed by a HFUS prototype (developed by the Helmholtz Institute for Biomedical Engineering, RWTH Aachen University, Aachen, Germany) by immersing each sample in a water basin filled with tempered (37 ☌) degassed isotonic saline solution (0.9% NaCl). To propagate, ultrasound waves need a medium such as water. Therefore, the aim of this study was to evaluate the accuracy of a HFUS for measuring peri-implant bone surrounding implants in comparison with CBCT and optical scanning as a reference method. However, the accuracy of this technique must be further evaluated. In a recent study this technique was used in association with a lower-frequency ultrasound probe to determine the cortical bone thickness in a dental implant model, and the results showed values similar to those of the CBCT measurements.

When this a priori information of a dental implant position has been obtained, the relationship between the dental implant and bone can be reconstructed, and the thickness of buccal bone surrounding the implant can be determined. Considering that both the ultrasound and the optical scanner are capable of providing information about the crown surface, which is outside the bone, the two images can be matched.

After the implant has been inserted into the bone surface, the ultrasound scan is performed. First, the implant with its crown is scanned with an optical scanner device. For this purpose, an optical scanner is required. To determine the exact three-dimensional (3D) position of a dental implant within the bone, a priori information from a dental implant containing a screw-retained crown (before placement in the bone) is necessary. Ultrasound, at this frequency, however, is able to scan the bone surface through thin soft-tissue layers, but hardly its inner portion. In these studies, nominal frequencies in the range of 40 MHz were applied to meet the higher demands concerning resolution and accuracy. Recent studies have shown that high-frequency ultrasound (HFUS) is a reliable technique for assessing peri-implant bone.

0 kommentar(er)

0 kommentar(er)